Quality Witness

-

01INGENVITYPowerful R&D Team

Polishing process--Xiaoying Zhao

ŌĆ£My position is the most ordinary one, and my hands is the most cherish weapon for supporting the familyŌĆÖs living. I hope that each part send out from my hand will be the perfect artwork. ŌĆØ

45┬░Angle of sand paper burnish, showing the meticulous skill with Pure manual polishing process; 25% the secondary grinding time decides the affection of eliminating grain of moldŌĆÖs surface. When the surface roughness reaches to ╬╝m level, it will be like a real mirror. -

-

02EXQUISITE STRATEGYProduce boutique molds to strengthen the country construction.

[Accuracy Capacity] The machining tolerance can be up to ┬▒0.001mm for high precision parts, ┬▒0.01mm for injection molds and sheet metal dies, and ┬▒0.002mm for precision sheet metal dies.

[Equipment Capacity] Full range Japanese imported equipments with famous brands Makino, Mitsubishi and Toshiba. The tolerance can be up to ┬▒0.01mm.

-

-

03DELIVERY TIMEShorten the mold delivery to achieve the maximization of customer benefits

[Design Management] Advanced parallel design technology with CAE/CAD/CAM, shorten 1/2 delivery time.

[Internal Logistics]U shape layout reduces waste of process flow, creating a convenient and efficient logistics environment to realize standardized logistics management.

[Planning Management] Advanced APS planning system and ERP system, distributes and monitor manpower, equipment and material reasonably.

[Machining Management] Optimized machining technology and widely-used CAM automatically, increase machining efficiency and shorten time effectively. -

-

04QUALITY CONTROLComplete Quality Control System, Provide Perfect Quality Service to Customer

Established standard quality control system and special quality management department to ensure the quality with high precision testing facilities combined with automated testing method and standardized control processes on incoming quality control(IQC),forming quality control(IPQC) and output quality control(OQC).

-

QC Management

- 01QualityQuality Assurance

- 02DevelopmentDevelopment and Design

- 03IncomingIncoming administration

- 04MangementIPQC ŌĆó FQC ŌĆó OQC

-

-

01Standard of quality guarantee system

For each order, Gree Daikin would follow with the strick quality guarantee system, from getting orderŌåÆpart analysisŌåÆstarting designŌåÆbuying steelŌåÆmaterial specificationŌåÆmanufacturingŌåÆprocess control inspectionŌåÆassembly & mold trial ŌåÆmold shipping, in order for 100% satisfaction from our customers.

-

-

02Strict Research & design analysis order of each order

For part quality, we have strict plan & quality judgment from the beginning of pre-study to finish design & review. Related documents would be provided at each period from getting order ŌåÆ part analysisŌåÆdesign reviewŌåÆdesign inspection, to make sure the shortened designing time at the premise of high quality.

-

-

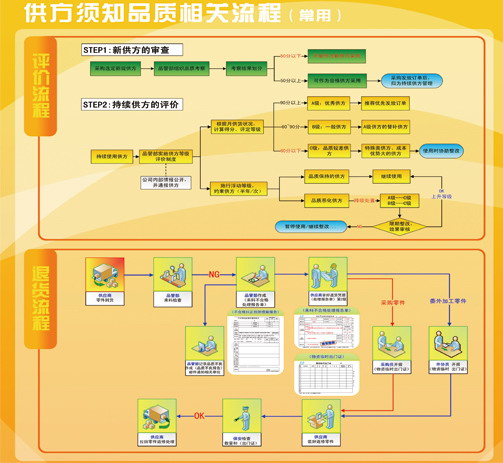

03Management of material supplier chosen

To guarantee the quality of steel material , we have three countermeasures for steel material : Steel inspection when arriving, supplier investigation, regular evaluation for supplier. Before buying steel, we would have strict inspection for the qualification of the supplier; After deciding supplier, inspection & supervising would be kept on for each month to analysis the steel quality. For the supplier who offer not satisfactory steel, guidance & correction would be given before starting the following process.

-

-

04All Staff Management during manufacturing

To make sure the quality & safety during manufacturing, every staff have to follow the ŌĆ£3-donŌĆÖtŌĆØ principle. ( DonŌĆÖt accept , donŌĆÖt manufacture and donŌĆÖt sell the disqualified molds & components)

China Quality Credit Enterprise

China Quality Credit Enterprise 2013 safety cultural construction model of Guangdong Province Enterprise

2013 safety cultural construction model of Guangdong Province Enterprise

WeChat

WeChat